A new peer-reviewed analysis of sources of leaks in natural gas drilling and well operations strongly bolsters growing calls for the Environmental Protection Agency to settle on regulations cutting wasteful, harmful emissions of methane from both new and existing oil and natural gas wells.

Methane is the main constituent of natural gas but also a powerful heat-trapping gas that is often accompanied by other pollutants that can worsen local air pollution.

The study, by researchers at the University of Texas and URS, a consulting firm — with the cooperation of (and some funding from) the oil and gas industry and Environmental Defense Fund (more on that below) — shows that much of the pollution problem lies in a small subset of poorly operating systems or faulty processes — in this case valves run pneumatically using the pressure of extracted gas and operations that clear liquids from older wells.

Here’s what leakage from pneumatic controllers on a well looks like, thanks to infrared video posted by the Clean Air Task Force (tripod next time, guys?):

When I asked Steven Hamburg, chief scientist for the Environmental Defense Fund, to describe the policy significance of the findings, he replied:

The study finds that one in five sources were high emitters — and the only way I know to address that problem is through comprehensive regulation of new and existing sources. We can’t just focus on new wells and infrastructure – we need a policy for the tens of thousands of wells, compressors, and other equipment that are already operating. Ignoring existing sources would leave some 90 percent of the oil and gas industry’s projected 2018 emissions unregulated.

Here are some of the basics from the University of Texas news release:

The UT Austin-led field study closely examined two major sources of methane emissions — liquid unloadings and pneumatic controller equipment — at well pad sites across the United States. Researchers found that 19 percent of the pneumatic devices accounted for 95 percent of the emissions from pneumatic devices, and 20 percent of the wells with unloading emissions that vent to the atmosphere accounted for 65 percent to 83 percent of those emissions.

“To put this in perspective, over the past several decades, 10 percent of the cars on the road have been responsible for the majority of automotive exhaust pollution,” said David Allen, chemical engineering professor at the Cockrell School and principal investigator for the study. “Similarly, a small group of sources within these two categories are responsible for the vast majority of pneumatic and unloading emissions at natural gas production sites.”

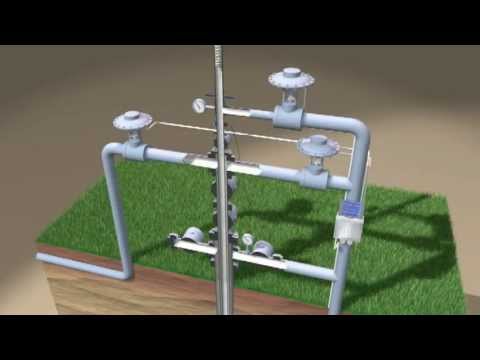

Click here for a presentation on the pneumatic controllers and here’s a presentation on the plungers and processes that are used to extract liquids that can reduce the gas flow in older wells. Here’s a University of Texas animation.

So far, the E.P.A. has been focusing its rule-making on requiring measurements of emissions, not mandatory reductions.

As I first wrote with Clifford Krauss in 2009, the industry’s tendency to drill new wells rather than tighten up old ones is both a pollution problem and a waste of a valuable fuel.

In a Dot Earth post at the time, I focused on a fascinating case study from BP’s gas fields in northern New Mexico, which showed that more careful use of the plunger systems can greatly cut gas loss (and thus methane emissions) — and do so at a profit.

Ferguson Beauregard, a manufacturer of computer-controlled plunger lift systems, has an informative video showing how these systems work (unrelated to the leakage question):

For more, read my recent piece on “Waste Not: Common Sense Ways to Reduce Methane Pollution from the Oil and Natural Gas Industry,” a set of recommendations from a coalition of environmental groups.

Here’s the question I posed to Hamburg about industry’s role in the research (slightly cleaned up from the email):

Like the gas team at the Environmental Defense Fund and the researchers at the University of Texas, I’m convinced that the only way toward more precision on sources of methane and opportunities for improvement is by working with the oil and gas industry to gain access to facilities and insights from those working these systems around the clock.

But that leads to a higher credibility bar — with some folks saying it’s impossible not to alert industry ahead of time when choosing sample facilities, etc. What is the source of your confidence that these findings are accurate and reflect broader realities?

Here’s Hamburg’s reply:

The concern that has been stated — that industry participation may mean these results represent a best-case or best-in-class scenario — is a valid one. No one study gives you the whole picture and that’s why we are also doing top-down studies etc. But let’s be clear, these results make a crystal clear case that comprehensive regulation is needed to address the problem of methane emissions. Other studies, some showing higher emissions, make the same case.

We have also been looking at fence line measurements, off site without permission, taken as part of other efforts and there are no substantive differences overall in the patterns we see from the UT results. Further, we have been doing top-down and bottom up comparisons in the Barnett based on measurements from 10 different research teams. We are not ready to go on the record with the results – the comparison shows no substantive differences between to-down and bottom up measurements – which means the underlying emissions factors can’t be too far off.

Regarding whether the companies cleaned up sites before measurements it is very hard to measure and adjust/change the operational characteristics of many of the things being measured in the period between when companies knew where the researchers were headed and when they arrive. It is also very unlikely given that it would take a concerted effort by the company to measure emissions, which is seldom done, need to make changes without making it obvious, new valves, equipment, etc., and do that at many sites in rapid succession.